What is the Best Grease for my Car?

Do you know that grease comes in different types and grades? If not, continue to read on to better understand and be able to select the best grease for your car based upon what you're planning to grease and the elements to which these critical automotive components will be exposed.

Learning which type is good for your vehicle and using it will extend the reliability period of your transportation. The market is flooded with products, HOWEVER it takes hours of research to discover the right product for you. Fortunately, we've done that for you.

Today we will provide you with some inside knowledge about the miraculous paste that offers lubrication and protection from the elements to your cars "joints", popularly known as Grease!

Grease is widely used in all mechanical machines that have moving parts because they all need lubrication. Lubrication reduces friction and as a secondary effect it extends the useful lifespan of the components. It does this by forming a protective film between moving parts that come into contact. This reduces heat and also protects the components from the elements.

Components that are moving and coming into contact with others are present in pretty much all industries. Therefore grease is present in all places, however not in the same form as not all mechanical machines and components are identical. It comes in different types and specifications such as AP, MP and EP.

The formula evolved from plain and simple to very specialized. This enables grease to be used in various environments that differ a lot and keep up with today's applications.

What are the different types of grease?

AP Grease

AP grease is lithium based and was designed to be multifunctional and withstand high temperatures + water contamination.

AP initials stand for ALL PURPOSE. It is mainly used on water pumps, chassis fittings, wheel bearings and universal joints. Users out there love that is provides great protection against corrosion and rusting.

The formula behind AP provides good thermal and structural stability which enables a very high melting point (drop point). Thanks to this, it is commonly used in all grease-lubricated automobile parts including commercial vehicles as well as parts that come into contact with water.

MP Grease

Or Number 2 Grease – as the National Lubrication Grease Institute calls it – is the type that is recommended for most light transport applications, agriculture and automotive. Mainly used for chassis lubrication and steering linkage joints. Reason is that besides lubrication it also coats the components in a wash-proof layer that protects them from the elements. This added protection helps extend these components life and reduce the risk of premature wear.

MP initials stand for MULTI PURPOSE. Being designed to be used in all types of environments, it supports a wide range of temperatures without losing any of its characteristics. The unique formula behind it helps it to maintain a stable composition when hot and also remain flowable when cold, allowing for it to have a smooth structure and be easily pumpable.

EP Grease

Is the type that is used in heavy applications and very high friction environments. Applicable wherever AP or MP grease is called for but the user fears that AP or MP might not do the job properly.

EP initials stand for EXTREME PRESSURE. Designed solely to provide the best protection under high pressure or shock loading. Regular grease, if compressed, extends the protective film until it breaks and the once greased parts come into contact with one another resulting in friction and wear.

This is where EP shines, as under high pressure or shock loading, despite the fact the the protective film expands just as other grease types, it does not “break” under extreme pressure.

Protection under heavy loads is given by it’s solid lubricant components, namely graphite and/or molybdenum disulfide. These enhance the normal protective film of the lubricant and bond to the surface of the metal it is applied to. Adding a sub-layer to the metal, it prevents metal to metal contact and the apparition of grease even if the lubrication film gets very thin or breaks. You can read more about this subject in our other article part 1 and part 2

Are There Different Grades of Grease?

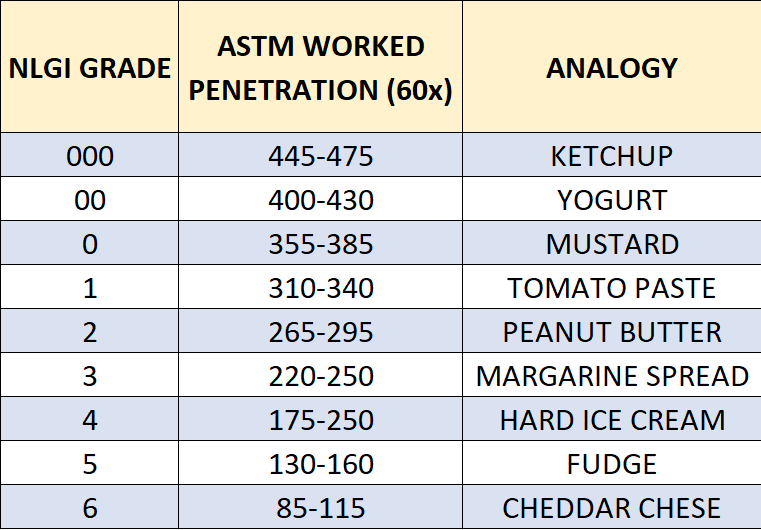

There are generally 9 consistency grades established by the NLGI that run from 000 (nearly fluid),00,0,1,2,3,4,5,6 (nearly solid)

They undergo a classification test in order to establish their grade. Usually the grade is determined by it’s worked penetration value. This test measures how deep a standard cone can fall into a grease sample in the tenths of a millimeter. Grading is given depending in what penetration ‘worked’ value range the measurement falls into. For example, high penetration values, as those over 335, indicate a low NLGI grade number.

What influences the NLGI grade is the base oil viscosity and the thickener amount in the formula. Thickeners function like a sponge, releasing lubricating fluid when force is applied. The lubrication fluid is made out of base oils and additives.

With consistency, comes more resistance to releasing the lubricating fluid under force. Low consistency means that the lubricating fluid is released under minimum force, while high consistency indicates the opposite. It is vital to choose the right consistency because if grease is too soft, it can move away from the area that needs to be lubricated. If it’s too stiff though, it may not migrate to the area at all, leaving those areas that need to be lubricated… exposed.

To make it easier to understand we put together a table with the NLGI grade, worked penetration values and a similar consistency element to make it easier to understand.

What are the uses of grease?

Use cases for grease depend solely on the grade in which is falls. Below are general guidelines. Consult your owners manual or component specifications for the best results.

000-0 Grade:

These greases range from fluid to semi-fluid with a tendency to be less viscous than others.

They can be very beneficial in centralized and enclosed applications where migration of the grease does not impose any issues.

Applications that fit this type are for example gear boxes. These require a grease within this range in order to achieve a continuous replenishment of the lubricant in the contact zone after it migrates off of the gears because of their spin or RPM.

1-3 Grade:

This grease range starts with grade 1 (similar to a tomato sauce) and ends with grade 3 (similar to butter).

One of the most common grease that is found is Grade 2; NLGI found in automotive bearings. However some automotive bearings as well as regular bearings also function with Grade 1 and Grade 3 NLGI grease. All within this range are capable of being operated in higher temperature ranges and higher speeds vs 000-0 Grades NLGI greases.

4-6 Grade:

This grease range exhibits more solid-like capabilities.

Grades 4-6 are better equipped to handle high speeds, where for example a Grade 4 NLGI grease can support 15,000+ rpm. Due to the speed of these devices, the level of friction and heat raises above normal.

A stiffer grease is required to ensure it does not become so fluid that it migrates off of the component . However, it also has channeling capabilities which means that under rotational power, its more easily pushed away from the component. Results in less churning and less temperature gain. Grades 5 and 6 NLGI are not usually used in applications as they are too viscous to qualify.

Additional Information:

For high pressure applications or applications where corrosion could prevent a components disassembly later in their service life, some greases have an extra element of copper . Grease that contains copper is also known as an anti-seize grease because it reduces the chance of electrolytic corrosion that “welds” together different metals that come into contact.

Forgive our shameless plug, however, one of the best greases as tested by independent third party labs, is CleanBoost® Mettle Plus Gold EP Grease which has a plus that no-other-grease-has … it “always stays in place at extreme loads and stresses” under the worst operating conditions of water, dirt and mud providing you with maximum protection and peace of mind.

You can use it on wheel bearings, disk brake applications, u-joints, fifth wheels, steering linkage and chassis lubricant on ALL of your equipment ranging from your lawn mower, scooter, motorcycle all the way to you car, truck, farming, off-road or industrial equipment application. With the melting point well over 650°F and Oxidation inhibitors, CleanBoost® Mettle Plus Gold EP Grease can get the job done even when exposed to high temperatures for extended periods.

About the Author

Tech Guy

Automotive enthusiast, passionate about Jeeps, hot-rods, turbos, performance, efficiency, diesels, fuels, high performance oils, additives and anything with an engine.