How to Prevent Diesel Fuel Gelling

“For truck drivers, the winter months are more than just that risky season when they have to be extra careful in driving. In fact, the cold months pose a lot more problems for them, one of which is diesel fuel gelling.“

Diesel fuel gelling happens when the paraffin usually present in diesel starts to solidify when the temperature drops. At 32 degrees, the wax in liquid form will crystallize and leave the fuel tank clouded. At 10-15 degrees, it will finally start to gel and clog the tank and fuel filters.

Gel Point and Pour Point in Diesel Fuel Gelling

Gel Point and Pour Point in Diesel Fuel Gelling

Gel point is the temperature point at which the diesel finally turns solid and can no longer flow through the fuel lines. Pour point, on the other hand, is the factor which determines the temperature at which a fluid starts to solidify.

In order for the diesel to flow better again, the gel point temperature should be brought back to the un-gel point which is around the temperature of the pour point. Unfortunately, the solidified waxes usually remain solid until its remix temperature is used to finally remelt or liquefy it.

Symptoms of Diesel Fuel Gelling

There are several signs that can tell you that your diesel has already gelled. One of these is when you are having trouble starting your engine. Diesel fuel gelling clogs the fuel lines and fuel filters, preventing the fuel to pass through them. This phenomenon then prevents the engine from starting.

Another sign is when there is a difference in the fuel rail pressure. This is likely the cause of problems like sluggish performance and inability to accelerate properly. Here, a difference between the desired fuel rail pressure and actual rail pressure is observed when accelerating. In these cases, the desired pressure usually spikes up while the actual pressure remains low because of the diesel fuel gelling stopping the fuel from getting where it should go.

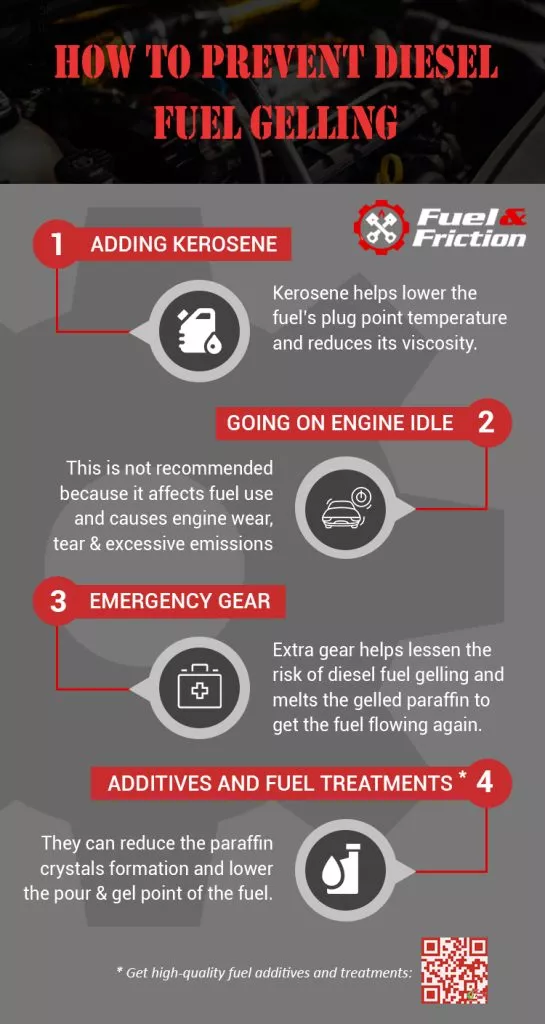

Ways to Prevent Diesel Fuel Gelling

Ways to Prevent Diesel Fuel Gelling

Adding Kerosene

It is a common practice for truckers to mix #1 diesel which has a blend of kerosene with diesel #2 which is used on road applications. Kerosene helps in lowering the plug point temperature of the fuel and reduces its viscosity, therefore making diesel less likely to gel even during low temperatures. Places in the extreme cold zones usually provide a winter diesel fuel mix like this. Unfortunately, it is not that easily available on places down south when hauling north.

Going on Engine Idle

Now if you go asking around, you will probably hear drivers suggesting to keep the engine running to keep the fuel from gelling. While this may work, it is not recommended at all for a couple of reasons. Not only does it negatively affect fuel use and diesel expense, it can also lead to engine wear, tear and excessive emissions.

Emergency Gear

Extra gear can help lessen the risk of diesel fuel gelling. Here, extra filters are needed to accommodate a cold flow treatment and a diesel emergency treatment. The cold flow treatment is used before going into the cold zone to prepare the fuel. The diesel emergency treatment, on the other hand, melts the gelled paraffin to get the fuel flowing again.

Additives and Fuel Treatments

Additives and fuel treatments are another common solution used to address diesel fuel gelling. Just like the earlier options mentioned, they also work to reduce the formation of paraffin crystals. They also lower the pour and gel point of the fuel as well.

A good example of a fuel treatment is CleanBoost® Sno-Cat™ Diesel Fuel Conditioner which is designed to reduce pour points and diesel fuel gelling in #1, #2, and even B5 and B20 Biodiesels. This quality additive is made with a unique blend of copolymers and fuel catalyst that prevents the formation of crystals. The way it works is that it prevents fuel system plugging by modifying the very crystals that usually form in the fuel during low temperatures. The crystals formed are smaller in size with the help of this additive, therefore preventing waxing and diesel fuel gelling. This product, moreover, also has a pour point depressant chemistry that improves the flowing capabilities of the fuel.

Additives like Sno-Cat™ also offers filter plugging prevention and stops water-related problems in the fuel. In addition to this, this product also increases range of the crude oil to be used in middle distillate production. Fuel technologies like these are also very helpful to those who don’t always have access to kerosene because it reduces the need for kerosene dilution in the fuel. It is also an EPA registered product so you are assured that you are also doing the environment a favor when using it.

Generally, fuel additives like Sno-Cat™ helps boost fuel economy by making the diesel fuel more efficient. It also helps trucks run smoother and longer during those winter hauls with its specialized wax forming prevention function.

If you want to know more about this product, simply go here.

Want a quick and easy solution to thaw gelled diesel fuel in an emergency? Read on to learn what to do in emergencies.

Here's a handy, printable infographic on How To Prevent Diesel Fuel Gelling:

About the Author

Tech Guy

Automotive enthusiast, passionate about Jeeps, hot-rods, turbos, performance, efficiency, diesels, fuels, high performance oils, additives and anything with an engine.