Microbial Growth in Fuel: What is it and How to Prevent it

“Fuel tanks and other storage systems are common thriving places for aerobic and anaerobic bacteria given the right set of conditions. When left untreated it can lead to the development of dirty slime in the fuel which can clog the filters and strainers in the tank. It can also cause tank corrosion and fuel spoiling.“

What is Microbial Growth in Fuel Storage and Tanks?

What is Microbial Growth in Fuel Storage and Tanks?

Diesel fuel tanks and storage systems play a very important role in marine, farming, and fleet operations. They help save money and time by insuring the safety and quality of reliable fuel. Just like anything else, these fuels need an effective maintenance strategy to function properly and deliver the results your looking for.

Microbial growth in fuel storage is triggered by fungal and bacterial growth. Fungus and bacteria have fuel as their primary source of food. They also prefer kerosene or diesel fuel over gasoline. The latter is not really a good food source for fungus because its composition contains lead and other elements which can act as poison to the bacteria.

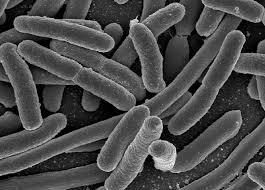

Being natural soil inhabitants, these microbes easily get carried via air. As a result, all fuels will contain some of them at a certain degree. These spores in their natural state are harmless. It is when they already start to germinate due to certain conditions, however, that they cause complications.

But what are exactly the conditions that promote microbial growth in fuel? There are three factors that may push this development. First is the presence of water, second is the food source (in this case a suitable fuel), and the correct temperature range which is 10C (50F) -40C (104F).

The condensation of water vapor within the diesel fuel tanks, moreover, also creates conditions suitable for microbial growth and contamination within the system. Severe contamination is needed by these microbes to grow and propagate. Since oil and water in fuel doesn’t mix, these microbes grow in the fuel-water interface which is usually formed at the bottom of the tank.

The microbial growth in fuel is usually described as near to the appearance of “chocolate mousse.” At severe conditions, large mats of slime will develop and block the filters in the fuel storage system. One very common fungus that flourishes in fuel is Cladosporium Resinae or “clad.” It was first discovered in aviation where it caused large-scale problems before finally controlled.

What are the Consequences of Microbial Growth in Fuel Tanks and Storage Systems?

What are the Consequences of Microbial Growth in Fuel Tanks and Storage Systems?

Fuel degradation is the primary result of microbial contamination in fuel tanks. One sign of the presence of contamination is the changing of fuel color. This problem can also lead to problems like reduced combustion efficiency, poor detergency, and elevated cloud and pour point. It can also increase the chances of fuel corrosion and also plug fuel filters.

How to Prevent Microbial Growth in Fuel

The best and most effective way of tackling this problem is prevention. Basically, keeping fuel tanks clean is one of the best methods to avoid contamination. This preventive evaluation of fuel tanks can be broken down into three parts namely:

a) Fuel monitoring program for the microbes

b) Fuel system maintenance

c) Fuel treatment

Fuel Monitoring

This part involves periodic testing and sampling of the fuel. Again, the main idea here is to minimize the problems through early detection of microbial growth. When monitoring, the test lab should follow procedures that are outlined in D-417-82 and ASTM D-4057-81.

Fuel System Maintenance

Fuel System Maintenance

The best way to prevent microbial growth in fuel is to lessen the exposure of the diesel fuel to water. There are various procedures that can do this such as recycling of fuel through water separations and routinely discharging the water bottoms where the microbes grow. Fuel tank insulation, a procedure to stabilize fuel temperature, can also be used.

In the event that sludge has already developed, it should be removed fast and on a regular basis to prevent it from growing. Scheduling regular tank inspection, cleaning, and treatments are also recommended. When it comes to treatment, preventative doses of diesel fuel biocides approved by the EPA should be used. These substances can prolong the time interval in between the need for tank cleanings.

Fuel Treatment

Fuel and water tank bottoms are recommended to be treated to control the spreading of microbial growth in fuel. Removal of the biomass or the sludge which has already developed is also needed. Again, diesel fuel biocide or a diesel microbial growth remover can help in preventing contamination. When choosing a remover, several factors should be considered namely the solubility of the fuel/water, compatibility with system components, compatibility with fuel and other additives, speed desired to kill the microbes, and of course industry and regulatory approvals.

A good example of a diesel microbial growth remover is CleanBoost® Anti-Microbe Fuel Conditioner. This product can be used in both diesel and bio-diesel fuels and is best added during the refilling of fresh fuel to the tank. It is capable of killing even the organisms that are hardest to remove in just a few hours. It also provides better resistance against hydrolysis. For more information please visit Boost Performance Products.

About the Author

Tech Guy

Automotive enthusiast, passionate about Jeeps, hot-rods, turbos, performance, efficiency, diesels, fuels, high performance oils, additives and anything with an engine.